Robotic CNC Machining

Panek Precision recognizes that in today's world of precision machining, higher throughput and achievement of zero defects have become the norm rather than the exception. To meet the challenge of this higher standard, strategic manufacturing processes within our facility have been fully automated and continuous integration of new robotic technology occurs on a monthly basis. The increased efficiency and quality that have been gained through this new technology provide ongoing benefit to our customers.

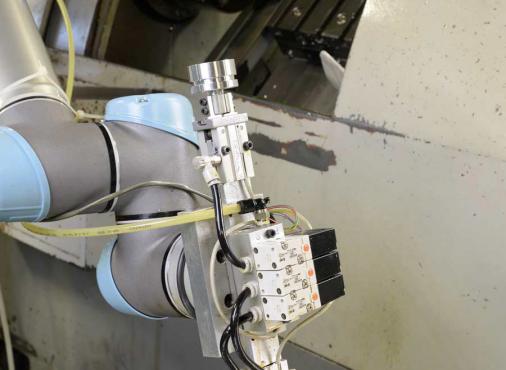

Panek Precision’s commitment to continuous improvement through ongoing investment in state-of-the-art technology is evident through its integration of robotics within its manufacturing processes. We have been early adopters and leaders in utilizing collaborative robots (65 and counting), and they have enabled us to successfully enhance the value and benefits to our customers

through a more cost-effective method of manufacturing. Robots facilitate more predictive throughput and quality through automated in-process and poke yokes, as well helping create a safer working environment for our employees.

Current Robotic Applications

- Process Inspections

- Load/Unload CNC & Secondary Machines

- Packaging of final product

- Product handling throughout production process

- Machining for secondary operations

- Buffing

- Deburring

- Countersinking

- Assembly

- Drill press operation

Industries Served

At Panek Precision, we specialize in delivering rapid turnaround and unmatched quality for manufacturers across a range of industries, including medical, automotive, military, garage access & security, controls & automation, cable connectors, marine, and aerospace.

Automotive

Our experience with multi-spindle and CNC machined automotive parts date back to the 1960s when we began serving the ride control and suspension markets.

Learn More >Military & Defense

Panek Precision is proud to manufacture components intended for use by the United States military.

Learn More >Garage Access & Security

Panek Precision manufactures garage door and security system components. We offer a variety of reliable options suitable for a range of systems.

Learn More >Controls & Automation

Panek Precision produces control and circuit breaker parts to meet your industrial, energy, and automation needs.

Learn More >Cable & Panel Connectors

Panek Precision produces panel connectors and industrial cable components. Our machining capabilities offer maximum functionality.

Learn More >