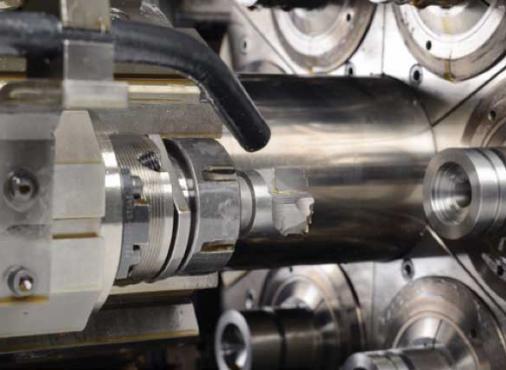

High Precision Multi-Spindle Machining

Panek Precision’s growth is attributed to the automatic screw machine going back to our founding date in 1945. Today, cam and CNC multi-spindle screw machining services remain a core part of our business for high volume, tight tolerance components.

Unlike most CNC machine shops, Panek Precision’s multi-spindle screw machines are capable of machining a wide range of bar stock sizes for components requiring multiple spindle screw machining – as small as 1/8 inch diameter up to 4 inches in diameter.

Our multi-spindle screw machine lineup includes Gildemeister screw machines, Davenport and New Britain, and our state of the art 6-spindle Index Traub CNC screw machine.

Multi Spindle vs. Single Spindle

There are several advantages to a multi-spindle screw machine versus single spindle technology. The main advantage is faster cycle times due to the machining operations being “split” from one spindle to multiple spindles. Essentially, these machines allow for multiple tools to cut multiple pieces of material simultaneously.

Panek Precision machines a wide range of bar stock sizes for high volume, tight tolerance components requiring multi-spindle machining – as small as 1/8 inch diameter up to 4 inches in diameter.

Multi Spindle Screw Machining Services

Our precision screw machining capabilities include:

| Gildemeisters | Gildemeister CNC | Index Traub CNC | Acme-Gridleys | Davenport | Other Screw Machines | |

| Quantity | 14 | 1 | 1 | 2 | 10 | 23 |

| Maximum OD (in) | 2-1/16" | 1-13/16" | 1-9/16" | 4" | 7/8" | 3.5" |

| Maximum OD (mm) | 50.8 -1.5875 | 25.4 - 20.6375 | 25.4 - 14.2875 | 101.6 | 22.225 | 88.9 |

Industries Served for Multi Spindle Screw Machining

At Panek Precision, we specialize in delivering rapid turnaround and unmatched quality for manufacturers across a range of industries, including medical, automotive, military, garage access & security, controls & automation, cable connectors, marine, and aerospace.

Automotive

Our experience with multi-spindle and CNC machined automotive parts date back to the 1960s when we began serving the ride control and suspension markets.

Learn More >Military & Defense

Panek Precision is proud to manufacture components intended for use by the United States military.

Learn More >Garage Access & Security

Panek Precision manufactures garage door and security system components. We offer a variety of reliable options suitable for a range of systems.

Learn More >Controls & Automation

Panek Precision produces control and circuit breaker parts to meet your industrial, energy, and automation needs.

Learn More >Cable & Panel Connectors

Panek Precision produces panel connectors and industrial cable components. Our machining capabilities offer maximum functionality.

Learn More >Multi Spindle Machining Materials

Our selection of raw materials available for machining include aluminum, brass, carbon steel, stainless steel, and various plastics. Our capabilities include high precision machining, metal tube cutting and end forming, assembly services, and 4-slide metal stamping.

Our Core Precision CNC Screw Machining Capabilities Include:

- Nine (9) multi-spindle Gildemeister screw machines with 2-1/8 bar capacity, back side “pick-up” spindles and tapping, threading & milling attachments

- Ten (10) multi-spindle Davenport screw machines for diameters as small as 1/8 inch up to 7/8 inch, back side “pick-up” spindles and tapping, threading & milling attachments

- Two (2) multi-spindle Acme-Gridley screw machines with 4 inch bar capacity for heavy duty jobs

Our Precision Cam and CNC Screw Machining Capabilities Include:

- Ten (10) Browne & Sharpe CNC screw machines with 2-3/8 inch bar capacity

- Nine (9) New Britain screw machines with 2-1/2 inch bar capacity