ISO Certified Machine Shop in Chicago

In keeping with our policy of total customer satisfaction, we go to great lengths to ensure the quality of our parts, and to continually improve our quality system processes in our iso compliant machine shop.

Holding an AS9100D with ISO 9001:2015, Panek Precision employs extensive quality control measures including APQP planning, statistical process control, an in-process inspection of parts to a C=0 sampling plan, and monitoring of production defects to determine their cause and eliminate them.

To ensure that our parts are always made using quality materials, we maintain strong relationships with a select group of outside suppliers. So we can always access top-quality materials, even for rush jobs when sourcing is time-sensitive. When it comes to quality, we know you have no tolerance for compromise. And neither do we.

Aerospace Certification Verification

Panek Precision’s customers have the utmost confidence in our ISO 9001:2015 and AS9100D certified quality management systems. These certifications are recognized as providing the maximum quality throughout the aerospace industry.

The AS9100D with ISO 9001:2015 is the most recent next step for organizations to design, develop aviation, space, and defense products and services, including parts and assemblies. This certification tailors to companies that provide products and services for the defense, space, and aviation industries. Panek’s combined quality certifications have produced less than ten defective parts per million produced, which the warrantee completely covers.

Panek Precision is ITAR-registered. Our registration code is # M43306.

Quality Assurance Lab Services

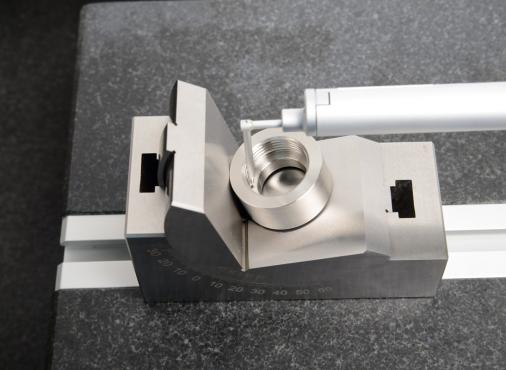

Our state-of-the-art quality assurance department features an array of advanced equipment and systems to ensure maximum precision and overall quality.

- Zeiss Coordinate Measurement Machine: In addition to probing, our CMM features full scanning technology allowing for increased accuracy and repeatability of tenths of a micron.

- Mitutoyo Surface Roughness Measuring System: Sealing surfaces continue to be more prevalent for component functionality. Our Mitutoyo not only checks standard roughness but is multi-axis capable for verifying difficult angle sand small surface areas.

- Thermo Scientific Niton Xl3t Analyzer: Adherence to raw material and coating specifications is mandatory in today's manufacturing world. Our Niton Analyzer gives you peace of mind by affirming chemical compositions of raw materials and coating thicknesses for finished components.